bluesign® Driving Strategic Transformation Toward a Safer and More Sustainable Fashion Industry

St. Gallen, January 27, 2025

As governments worldwide rapidly shift priorities in addressing sustainable fashion manufacturing, bluesign® emerges as a visible leader in the CLEAN CHEMISTRY MOVEMENT. Approaching 25 years of experience driving transformative solutions for the textile industry, bluesign® has become synonymous with advancing chemical management and environmental responsibility. The bluesign® SYSTEM is setting the benchmark for safer, more sustainable practices by eliminating hazardous chemicals, optimizing resource usage, and fostering transparency across our supply chain. In an era where the demand for accountability has reached a tipping point, their mission has never been clearer: to ensure worker and consumer safety while driving measurable environmental impact reduction and shaping a sustainable future for the textile industry.

With news headlines like “Fast Fashion is Made with Alarmingly High Amounts of Toxic Chemicals” (Business Insider) the textile industry continues to be under intense scrutiny as revelations about the widespread use of hazardous chemicals highlight significant risks to human health and the environment. Recently released reports expose alarmingly high levels of toxic substances such as PFAS , phthalates, lead, and cadmium in clothing – ranging from children’s garments to activewear, raising urgent concerns about consumer safety and environmental impact.

Celebrating its 25th year in progressing the clean chemical movement across fashion, bluesign®, a key brand within SGS’s sustainability portfolio, has been an industry leader in chemical management, environmental management and resource optimization for the textile industry. Leveraging SGS’s global network and proven leadership in sustainability and digital trust, bluesign® combines scientific excellence with innovative and actionable solutions to address the textile industry’s most pressing challenges.

Addressing Today’s Challenges with Our Solutions

With over 800 partners globally from household name brands to manufacturers and chemical makers, the bluesign® SYSTEM focuses on clean chemistry, clean manufacturing, and clean products to ensure worker safety, consumer safety, and reduced adverse environmental impact.

A key component of the system is its proactive approach to chemical change management. By working directly with chemical suppliers, textile manufacturers, brands, and retailers, bluesign® sets stringent criteria to eliminate carcinogenic, mutagenic, and toxic-for-reproduction (CMR) substances, while providing more sustainable alternatives. This not only ensures the safety of workers exposed to these chemicals during textile manufacturing but also enables brands to deliver textile materials and products that are safer for their consumers to enjoy.

Additionally, the bluesign® SYSTEM minimizes resource consumption by optimizing water, energy, and chemical usage, with tailored action plans to minimize this consumption, leading to a significant reduction in environmental impact.

By focusing on delivering measurable sustainability outcomes using a collective approach powered by decades of expertise, bluesign® reinforces its commitment to driving tangible progress in protecting human health, the environment, and natural resources.

A Call for Action

As consumer awareness of toxic chemicals in textiles grows, the demand for transparency and accountability in the industry has never been stronger. bluesign®, a trailblazer, stands as a beacon of trust, innovation, and responsibility, proving that safer and more sustainable textiles are not just possible—they are essential.

Daniel Rüfenacht, CEO of bluesign®, emphasizes the importance of proactive industry transformation:

“The textile industry stands at a critical crossroads. For 25 years, we have been setting and evolving rigorous standards by successfully empowering chemical suppliers, textile manufacturers, and brands to adopt safer, more sustainable practices. In collaborating with stakeholders across the value chain, we are shaping the future of textile production, proving that innovation and responsibility go hand in hand, and creating lasting value for people and the planet.”

bluesign® Welcomes Designer Denim Maker, LIM Group

First Laundry in Italy to become System Partner

[11/25/2024] As part of their growing denim initiative, bluesign®, the leading global sustainability solutions provider for the textile industry, proudly announces LIM Group as their first laundry system partner in Italy. This partnership enables bluesign® to be a one-stop resource for LIM teams working with top designers, luxury houses, and international labels on their denim programs. Recognized as the gold standard in chemical management, bluesign’s impact reduction work in the textile supply chain has gained even more importance regarding compliance with the EU legislation such as CSDDD, CSRD and ESPR. With LIM’s exceptional craftsmanship and bluesign®’s trusted expertise, this collaboration sets a new standard for European clean denim manufacturing.

Founded and managed by the Stevanin family since the 1980s, LIM’s laundry has distinguished itself in the fashion industry with its expertise in denim washing and unique dyeing techniques. LIM also integrates eco-friendly technologies, including ozone and laser machinery, wastewater purification systems, and renewable energy-powered operations. With a strong reputation for creativity, technical expertise, and eco-conscious practices, LIM collaborates with some of the world’s most prestigious brands and luxury houses, including Valentino, Balenciaga, Gucci, Dsquared2, Maison Margiela, Replay, Jacob Cohen, and Dondup

“Renowned for its expertise in washing and dyeing processes while working in collaboration with the world’s top names, LIM has established itself as a leader in the denim industry. Their integration into the bluesign® system reinforces the importance of bluesign in fostering sustainable practices in laundry and dyeing. We are excited to work with the Stevanin family and LIM Group teams globally as they help us expand the reach of our mission to enable clean denim manufacturing globally.”

Daniel Rüfenacht, CEO of bluesign®

As the first bluesign® laundry system partner in Italy, LIM Group is at the forefront of reshaping the country’s textile manufacturing landscape. The company’s use of advanced technologies aligns perfectly with bluesign®’s vision for reducing resource consumption and environmental impact.

“Joining the bluesign® system marks a pivotal moment for LIM as we continue to prioritize sustainability in our operations and with our brand partners. Our relationship not only strengthens our commitment to eco-conscious manufacturing but also enables us to deliver innovative solutions that meet the expectations of today’s conscious consumers. We are proud to collaborate with bluesign® to set new standards for transparency, accountability, and sustainable production.“

Gianfranco Stevanin, CEO and Co-Owner of LIM Group

About bluesign®

The bluesign® SYSTEM is the solution for sustainable textile production. It eliminates harmful substances right from the start of the manufacturing process, and it sets and controls standards for environmentally friendly and safe production. This not only ensures that the final textile product meets very stringent consumer safety requirements worldwide but also gives the customer confidence in purchasing sustainable and safe-to-wear products. Since its founding in 2000, bluesign® has partnered with over 850 manufacturers, brands, and chemical suppliers worldwide, driving transformative change in the textile industry. Various well-known brands in the outdoor, sportswear and fashion industry partner with bluesign® and trust its extensive knowledge and services to collectively reduce the textile industry’s impact on people and the planet.

bluesign® is part of the $7-billion+ SGS family of companies.

SGS is the world’s leading testing, inspection, and certification company.

About LIM Group

Since the 1980s, LIM Group has been at the forefront of the fashion industry, offering premium washing and dyeing services for denim, fabrics, leather, and accessories. Known for its creativity, technical expertise, and eco-conscious approach, LIM collaborates with major luxury and Made in Italy brands to develop innovative solutions tailored to their unique needs.

As a company deeply committed to social and environmental sustainability, LIM continually invests in improving safety, reducing resource consumption, and adopting state-of-the-art technologies to minimize its environmental footprint.

SAITEX MILL in Vietnam Joins as bluesign® System Partner

Part of bluesign’s Global Denim Initiative

bluesign® is proud to announce that SAITEX Mill has officially become a bluesign® System Partner. This collaboration marks a significant milestone in bluesign’s Denim Initiative, furthering the mission to drive sustainability across the global denim industry. SAITEX Laundry, the first denim laundry globally to join bluesign as a system partner over a decade ago, has now been joined by SAITEX Mill, creating a powerful, end-to-end sustainable production solution under one roof.

Founded by Sanjeev Bahl, SAITEX is a global leader in sustainable garment manufacturing, known for its innovative approach to reducing the environmental impact of textile production. Founded in 2001, the company operates with a commitment to sustainability, circularity, and social responsibility. With facilities in Vietnam and Los Angeles, SAITEX employs cutting-edge technologies such as closed-loop water systems, energy-efficient processes, and clean chemistry to minimize waste and carbon emissions. The garment operation is bluesign®, Fair Trade, LEED, and B Corp certified, underscoring its dedication to ethical manufacturing practices.

SAITEX partners with leading global brands to create high-quality denim and apparel while continuously pushing the boundaries of responsible production, setting a benchmark for the future of fashion.

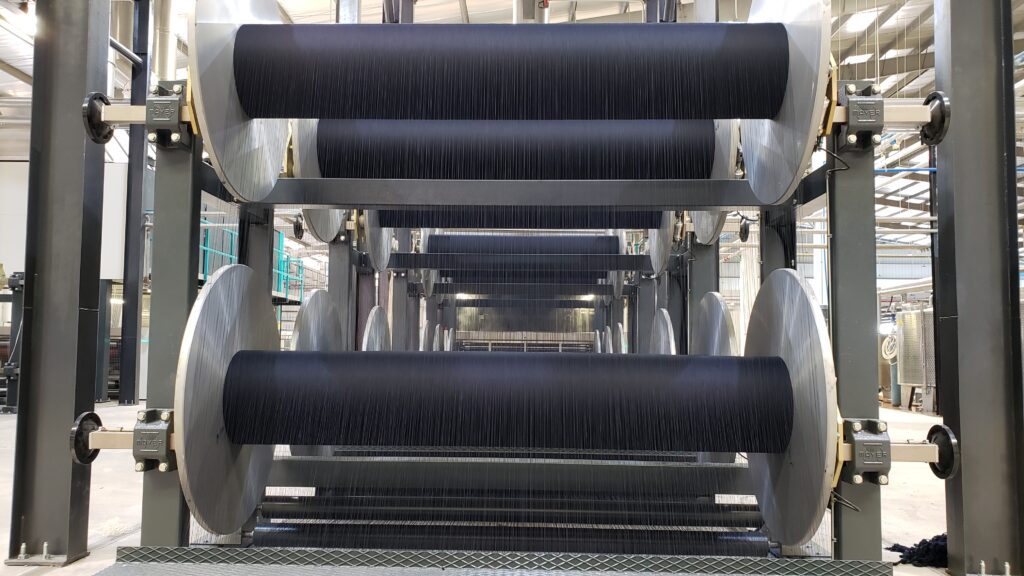

Opened in 2022, SAITEX’s cutting-edge fabric Mill near Ho Chi Minh City, Vietnam, represents the next generation of sustainable manufacturing. The mill integrates spinning, weaving, dyeing, and finishing processes under one roof, with a core focus on environmental responsibility. Leveraging advanced technologies, it reduces energy consumption, minimizes the use of harmful chemicals, and is on track to build a closed-loop water system to minimize freshwater intake, which will be completed by mid-2025. This state-of-the-art facility reflects SAITEX’s commitment to setting new standards for responsible production and circularity in the global textile industry.

Now that both the SAITEX mill and laundry are bluesign® system partners, brands can label their denim garments as bluesign® DENIM, produced and processed entirely within SAITEX’s facilities. The bluesign® DENIM label requires that the denim fabric is bluesign® APPROVED from a system partner mill, and that the garment is processed in a system partner laundry, ensuring compliance with bluesign’s strict environmental criteria. This allows brands to source bluesign® APPROVED denim fabrics directly from SAITEX Mill, have the garments processed at SAITEX Laundry, and achieve an end-to-end clean denim production process for consumers. With bluesign® APPROVED chemicals used in both fabric manufacturing and garment processing, brands can easily meet sustainability standards with SAITEX as their one-stop solution for clean denim.

This partnership aligns with bluesign’s dedication to reducing the textile industry’s environmental footprint by ensuring that textiles are made with responsible resource usage and worker safety. By becoming a bluesign® System Partner, SAITEX enhances its commitment to eco-friendly production practices, offering transparency and traceability throughout the garment life cycle.

Key Highlights of the SAITEX Mill:

• The mill features solar panels with a 3-4 MW capacity, reducing carbon emissions by 2,000+ tons annually.

• The facility is designed with LEED Gold Certified specifications, ensuring minimal environmental impact through energy efficiency. LEED Gold certification is expected in November 2024.

• The mill utilizes Smart-Indigo™ technology for hydrosulfite-free dyeing, resulting in 90% less CO2 emissions, 70% less energy use, and 30% less water consumption.

• SAITEX aims to achieve carbon neutrality by 2030 through continued innovations in energy and resource efficiency.

• The fully vertically integrated mill, from spinning to garment manufacturing, ensures lower environmental impact on both the fabric and laundry sides of the production process.

“Becoming a bluesign® System Partner is another step in reinforcing our mission of sustainability, transparency, and responsibility. With bluesign®, we’re not just setting a new standard for responsible denim manufacturing; we’re driving a broader movement toward clean chemistry. This is about creating a system that’s safe for people and the planet—putting the human side of manufacturing at the center of everything we do. It’s our responsibility to ensure that our processes are as clean as they are efficient.”

Sanjeev Bahl, CEO of SAITEX

“We were proud to welcome SAITEX Laundry into bluesign over 10 years ago as the first system partner denim laundry in the world, and it is thrilling for us to now have SAITEX Mill join the system partnership as well. Brands can now source bluesign® APPROVED denim fabrics from SAITEX Mill for their collections, and with both the mill and laundry as system partners, they can label their denim garments as bluesign® DENIM, ensuring a fully compliant and sustainable production process under one roof. Together, we are making significant strides toward reducing the global environmental impact of denim production.”

Daniel Rüfenacht, CEO of bluesign®

This partnership strengthens bluesign’s Denim Initiative, which brings together key players in the denim industry to create safer, more sustainable denim products. With SAITEX’s vertical integration and advanced technology, the global denim market is one step closer to achieving environmental responsibility and social equity.

About bluesign®

The bluesign® SYSTEM is the solution for sustainable textile production. It eliminates harmful substances right from the start of the manufacturing process, and it sets and controls standards for environmentally friendly and safe production. This not only ensures that the final textile product meets very stringent consumer safety requirements worldwide but also gives the customer confidence in purchasing sustainable and safe-to-wear products. Since its founding in 2000, bluesign® has partnered with over 850 manufacturers, brands, and chemical suppliers worldwide, driving transformative change in the textile industry. Various well-known brands in the outdoor, sportswear and fashion industry partner with bluesign® and trust its extensive knowledge and services to collectively reduce the textile industry’s impact on people and the planet.

bluesign is part of the $7-billion+ SGS family of companies.

SGS is the world’s leading testing, inspection, and certification company.

About SAITEX

SAITEX is a leading sustainable denim manufacturer known for its innovative and eco-conscious approach. With operations in Vietnam and the USA, SAITEX focuses on reducing its environmental footprint while promoting social responsibility and transparency. Through its circular manufacturing processes and groundbreaking technology, SAITEX is revolutionizing the denim industry.

EU Strengthens Chemical Safety in Textiles

New PFHxA Restrictions Align with bluesign’s Broad PFAS Phase Out Program

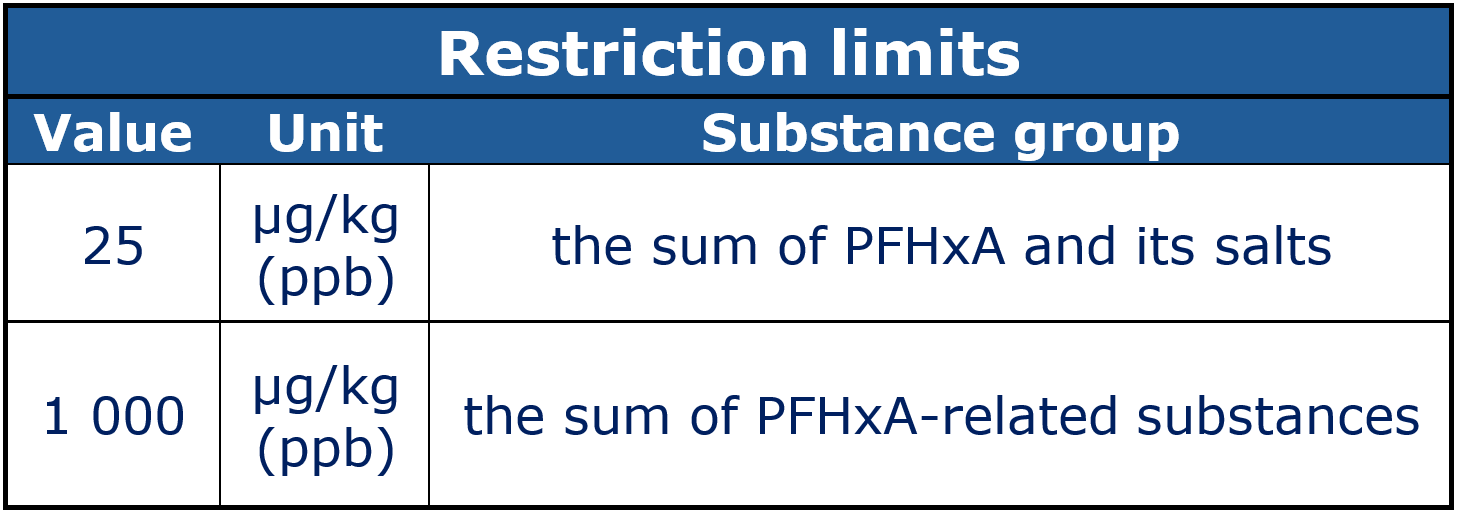

The European Commission has recently published the highly anticipated restriction on the use of undecafluorohexanoic acid (PFHxA), its salts, and related substances (Commission Regulation (EU) 2024/2462). This new restriction comes by way of adding entry 79 to Annex XVII to the REACH regulation. The decision was made due to PFHxA’s environmental persistence, its high mobility in aquatic environment, and its potential adverse effects on both human health and the environment.

PFHxA is a subgroup of PFAS (Per- and polyfluoroalkyl substances). PFHxA and its related compounds are widely utilized in several industries, notably in the production of textiles, paper, cardboard, and firefighting foams. In particular, these substances are used in the manufacture of water- and stain-resistant textiles, often found in outdoor clothing like rain jackets, and various accessories, such as handbags and footwear. The widespread and dispersive use of PFHxA in these products is of significant concern as it contributes to increasing environmental contamination and human exposure over time.

In light of this, the European Commission has deemed it necessary to implement a Union-wide restriction on the sale and use of PFHxA, its salts, and related substances in a range of consumer products. These include not only textiles like clothing, leather, and furs but also household items such as carpets, rugs, curtains, blinds, upholstery and food contact materials like paper and cardboard. The restriction extends to items used in public spaces and offices, particularly those frequently visited by the general public. Additionally, certain firefighting foams and cosmetic products containing PFHxA-related substances will be affected by the new regulation.

Transition Period

PFHxA, its salts and related substances shall not be placed on the market in the following products from the dates indicated below:

• textiles, leather, furs and hides in clothing and related accessories for the general public

• footwear for the general public

• paper and cardboard used as food contact materials

• mixtures for the general public

• defined cosmetic products

• textiles, leather, furs and hides, other than in clothing and related accessories referred to in paragraph 1, for the general public

Restrictions on the use of firefighting foams take effect on 10 April 2026, with an extended deadline of 10 October 2029 for firefighting foams used in civil aviation.

Several uses are exempted from the stipulated restrictions, namely the following:

• personal protective equipment intended to protect users against risks within the scope of risk category III, points (a), (c) to (f), (h), and (l) of Annex I to Regulation (EU) 2016/425

• devices within the scope of Regulation (EU) 2017/745 and 2017/746

• construction textiles

For more information, please refer to legal document.

bluesign’s Commitment to PFAS Phase-Out

In anticipation of raising environmental and human health concern towards PFAS substances bluesign has launched a broad phase out program in 2022 (see details here). The bluesign PFAS phase out goes beyond the scope of the PFHxA its salts and related substances by essentially covering all substances classified as PFAS. By January 1, 2025, all articles and consumer products labeled as bluesign® APPROVED and bluesign® PRODUCT must be manufactured without the intentional use of PFAS. Use our bluesign® GUIDE to get access to certified articles and consumer products that were produced without the use of PFAS and other harmful substances.

SanMar Joins bluesign®, Reinforcing Its Leadership in Sustainability

SanMar Corporation, one of the largest suppliers of promotional products in the United States, is excited to announce it has joined bluesign® as a system partner. This move underscores SanMar’s commitment to sustainable manufacturing and responsible chemical management, reinforcing its position as a leader in the promotional products industry.

As a bluesign® SYSTEM PARTNER, SanMar joins a global network of companies dedicated to reducing the environmental impact of textile production. By integrating bluesign® standards into their supply chain, SanMar will ensure that their supply chain continues to meet the highest environmental and safety criteria, aligning with their long-term sustainability goals.

“SanMar’s decision to partner with bluesign® is a testament to their dedication to sustainability and responsible manufacturing. Their leadership in the promotional products sector makes this partnership particularly significant. We are proud to support SanMar in their journey towards a more sustainable future, and we look forward to seeing the positive impact they will have on the industry.”

Daniel Rüfenacht, CEO of bluesign technologies ag

Through system partnership, SanMar is taking significant steps to enhance the sustainability of its product offerings, from material sourcing to production processes. By adopting bluesign® standards, SanMar is not only contributing to environmental conservation but also continues their commitment to ensuring that its products are safe for consumers and the planet.

“The awareness and importance of sustainability is growing within our industry, and we’re excited to add bluesign® to our bench. We look forward to leveraging the bluesign system and their team of experts to improve our programs and to continue providing our customers with products made to the highest environmental standards.”

Emily Gigot, Senior Manager of Sustainability at SanMar

Storm Creek Joins as bluesign® System Partner – First US Promotional Products Brand

Committing to 100% bluesign® Approved Fabrics by 2025

Storm Creek, a leading innovator in sustainable apparel within the promotional products industry, is proud to announce its official partnership with bluesign® as a system partner. This partnership marks a significant milestone, as Storm Creek becomes the first promotional products brand to join the bluesign® System, setting a new standard for sustainability in the industry.

As part of this commitment, Storm Creek has pledged to use only bluesign® Approved fabrics by 2025. Their upcoming 2025 product catalog will already feature a range of products made with bluesign® certified fabrics, demonstrating their dedication to reducing environmental impact and promoting safe, responsible production practices.

“This partnership takes our already strong commitment to sustainability to the next level. Our aim is to inspire and educate promotional products distributors to sell sustainably and increase the impact their end buyers can have. Storm Creek is proud to set the standard for the promo industry.”

Doug Jackson, Storm Creek Founder and President

Storm Creek’s partnership with bluesign® aligns with their mission to deliver high-performance, sustainable apparel while minimizing environmental impact. By adhering to the rigorous standards set by bluesign®, Storm Creek is not only ensuring the safety and sustainability of its products but also leading the charge in transforming the promotional products industry.

“We are thrilled to welcome Storm Creek as a promotional products brand to join the bluesign® System. Their commitment to using 100% bluesign® Approved fabrics by 2025 is a bold and commendable step towards a more sustainable future. Storm Creek’s leadership in this area sets an inspiring example for the entire promotional products industry.”

Daniel Rüfenacht, CEO of bluesign technologies ag

DONDUP Partners with bluesign® to Set a New Standard in Sustainable Denim

DONDUP, the renowned Italian designer denim brand, is excited to announce its official partnership with bluesign®. As the leading European denim company to join the bluesign® SYSTEM PARTNER network, DONDUP underscores its unwavering commitment to sustainability, responsible production, and environmental stewardship, setting a new benchmark in the fashion industry.

bluesign® offers a comprehensive solutions system focused on sustainable chemistry, employing a holistic approach to drive environmental improvements, enhance worker safety, and increase resource efficiency. Through rigorous on-site assessments, management of input streams, and verification of chemical inventories, bluesign® collaborates closely with its system partners to develop tailored solutions that ensure stringent safety and sustainability standards are met at every step.

DONDUP is now part of bluesign’s Denim Initiative, launched in March 2023, which includes a global network of leading denim brands, manufacturers, mills, and materials suppliers such as Everlane, Reformation, PureDenim, Saitex, Advance Denim, and ISKO. This initiative aims to revolutionize denim production by implementing clean chemistry and sustainable practices, ensuring the highest standards of safety and environmental responsibility.

“At DONDUP, our commitment to sustainability and responsible production is unwavering. By partnering with bluesign®, we are advancing our mission to minimize environmental impact and uphold the highest safety and responsibility standards in our supply chain. This collaboration allows us to produce stylish, environmentally conscious, and socially responsible premium denim.”

Matteo Anchisi, CEO of DONDUP

The ripple effect of DONDUP’s partnership with bluesign® extends beyond the brand itself. As bluesign’s clean chemistry practices are implemented throughout DONDUP’s supply chain, they inspire other stakeholders—suppliers, manufacturers, and even raw material providers—to adopt similar standards of environmental and social responsibility. This cascading effect ensures that every aspect of the production process, from chemical suppliers to material manufacturers, aligns with the stringent environmental and social criteria set by bluesign®.

“We chose bluesign® as a trusted partner to ensure our production processes meet stringent environmental and social criteria. Together, we are setting a new standard for sustainability in the fashion industry, prioritizing transparency and accountability. We are proud to lead the way in sustainable denim and anticipate the positive impact this partnership will have on our products, industry, and the world.”

Matteo Anchisi, CEO of DONDUP

DONDUP’s partnership with bluesign® is expected to create an echo effect throughout the fashion industry, encouraging numerous materials vendors, manufacturers, and other partners to join bluesign®. This collective movement towards cleaner and more sustainable production practices will further amplify the impact of this partnership, driving significant improvements in environmental and social responsibility across the supply chain.

ERCA Becomes First bluesign® System Partner in Brazil

Expanding Global Reach of Chemical Management System

bluesign® thrilled to announce that ERCA, a leader in innovative chemical solutions for the textile industry, has become the first bluesign® system partner in Brazil. This milestone marks a significant step in bluesign’s global expansion, further solidifying bluesign® presence across numerous continents.

As part of the ERCA Group, which operates with manufacturing plants in Europe, Latin America, and Asia, ERCA is dedicated to responsible innovation and sustainability. The company is renowned for its cutting-edge chemical specialties, including their revolutionary REVECOL® range, which transforms waste materials like exhausted vegetable oil into high-performance textile solutions, and is bluesign approved.

ERCAs commitment to transparency and environmental responsibility aligns perfectly with bluesign’s mission to drive sustainable practices within the textile industry. By partnering with bluesign, ERCA Brazil underscores its dedication to reducing environmental impact and ensuring the highest standards of safety and sustainability in its products.

“We are immensely proud to be the first company in Brazil to become a bluesign System Partner. This achievement reflects our team’s tireless efforts to prioritize sustainability and responsible manufacturing. We believe that bluesign’s rigorous standards will not only benefit our company, but also our customers and the environment.

The benefits of being a Bluesign System Partner are numerous. For Erca Brazil’s customers, this certification ensures that products are manufactured using safe chemicals, reducing the risk of harmful substances in the supply chain. This commitment to safety and sustainability aligns with the growing consumer demand for environmentally responsible products.

Furthermore, Erca Brazil’s bluesign System Partner status demonstrates its dedication to resource conservation and energy efficiency. By implementing bluesign’s best practices, Erca Brazil can reduce its environmental footprint and minimize waste throughout its operations.“

Sidnei Maturano, ERCA Brazil’s President

This partnership not only highlights ERCA’s leadership in Brazil but also reflects bluesign’s growing influence and commitment to sustainability across the globe. With partners now spanning multiple continents, bluesign continues to lead the charge in transforming the textile industry for a more sustainable future.

We congratulate ERCA Brazil on this achievement and look forward to our continued collaboration in driving innovation and sustainability worldwide.

bluesign Standards: Reducing Bisphenol Risks in Sustainable Textile Production

Bisphenols are a group of chemicals mostly used in the industrial manufacturing of polymers such as polycarbonate plastics and epoxy resins. These materials are used across a range of consumer products, making them common in many everyday products. The most widely used and known is bisphenol A (BPA), although following the restrictions on the BPA leads to the increasing volumes of bisphenol S and bisphenol F that may be equally harmful.

What is the concern about bisphenols?

Health impact:

Bisphenol A (BPA) is well known as an endocrine disruptor – can mimic human estrogen and therefore may affect fertility and disrupt the development of unborn child. In addition, BPA is also linked to several adverse health outcomes including cardiovascular diseases, hormone related cancer risk, obesity, and metabolic diseases.

Environmental impact:

Bisphenols leaching into water supplies and soil may lead to long-term ecological damage. Aquatic life, in particular, is at risk as bisphenols can disrupt the hormonal balance of fish and other organisms.

Moreover, Bisphenol A is classified in the EU as a substance that:

• causes toxic effects on our ability to reproduce

• causes serious eye damage

• may cause respiratory irritation

• may cause skin allergies

• very toxic to aquatic life

• very toxic to aquatic life with long lasting effect

Did you know?

Bisphenol A has been detected in the urine of 92% of adult research participants covering 11 European countries in the concentration exceeding safe level.

Are there any legal restrictions on bisphenols?

Bisphenols, especially BPA, are subject to various legal restrictions and regulations worldwide due to their potential health risks. Here’s an overview of some key regulations and legal lists where bisphenols are restricted:

European Union

• The candidate list of substances of very high concern contains three bisphenols

• EU restriction proposal for bisphenols of similar concern (BOSC) with proposed limit 10 ppm for sum

• Currently covered BP A,B,S,F,AF

• REACH BPA restriction

• Its use in the thermal paper has been restricted since January 2020

• BPA has been banned in infant feeding bottles since 2011 and in plastic bottles and packaging containing food for babies and children since 2018

United States

• The Food and Drug Administration (FDA) restricts the use of BPA in baby bottles, sippy cups, and the packaging of infant formula

• Since 2015 BPA is listed in the California Proposition 65 as substance causing reproductive toxicity

• California prohibits children´s feeding/ sucking/ teething products containing bisphenols

• Listed on TSCA Inventory by Environmental Protection Agency (EPA) – regulating and monitoring chemicals in control to human health and environment

Canada

• BPA is identified as toxic substance under the Canadian Environmental Protection Act, 1999

• Regulations under the Canada Consumer Product Safety Act prohibit the manufacture, advertisement, sale or import of baby bottles containing BPA

• BPA is listed on Canadian Cosmetic Ingredient Hotlist as a prohibited substance for use in Cosmetics

China

• In 2011 the Ministry of Health announced the prohibition of manufacturing, import and sale of infant feeding bottles containing BPA

Where can be bisphenols be found in the textile industry?

Although the primary route of exposure to bisphenols is through diet, as these chemicals can leach from food packaging, it is important to be cautious about other potential contact pathways. Bisphenols can also enter the body through the skin by contact with items like textiles that may contain traces of these chemicals. Therefore, it is crucial to pay attention to the materials we come into contact within our daily lives to minimize overall bisphenol exposure.

Moving forward with bluesign!

Given the significant health and environmental risks associated with bisphenols, reducing, or eliminating their use is crucial. Protecting human health, especially vulnerable populations such as pregnant women and children, is a primary concern.

Bisphenols A, AF, B, F, and S, which are all currently listed by BOSC, are regulated under the bluesign® BSSL and BSBL. bluesign enforces a usage ban on BPA with one of the most stringent limits on the market, verifying compliance with most regulatory restrictions.

BPA from Chemicals and Consumer Safety

The use of bluesign® APPROVED chemical products guarantees BPA input at a very low level, based on the strict BSBL limit. Additionally, using bluesign® APPROVED materials and adhering to the Restricted Substances List (RSL) for sourcing ensures compliance with the highest market standards. Together with effective Input Stream Management (ISM) is the best strategy to ensure safety.

Textile recycling with bluesign

Textile recycling is a significant aspect of sustainability, but it often involves the unknown chemical mixtures including bisphenols.

This topic underlines the importance of the Input Stream Management. In general, reliable sources in combination with ISM and testing provide remarkable reduction of the potential exposure.

For bluesign® SYSTEM PARTNERS instruction regarding the use of recycled material is available in our guidance documents.

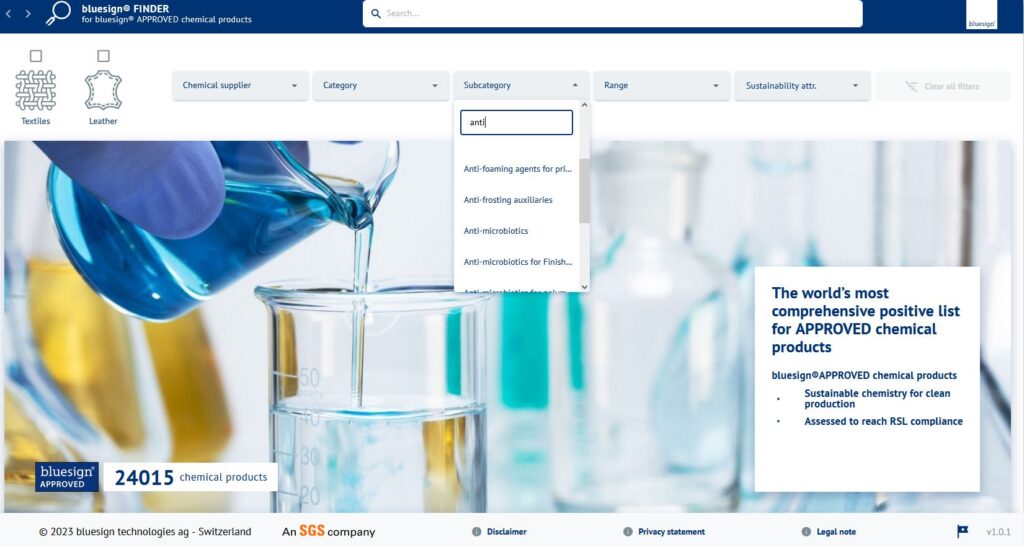

Alternatives? Use bluesign® FINDER

The push towards eliminating bisphenols in the textile industry involves finding safer alternatives that do not compromise the quality and functionality of the products. Research and development are focusing on biodegradable and non-toxic compounds that can replace bisphenols in various textile applications.

bluesign® FINDER offers the world’s most comprehensive positive list for APPROVED chemical products, all complying with strict bisphenol limits. It provides access to over 25,000 chemical products that support sustainable chemistry and clean production achieving the RSL compliance. Moreover, bluesign® FINDER offers nearly 200 bisphenol- free alternatives for aftertreatment agents.

With bluesign® certified textiles, consumers can confidently choose products ensuring safety and sustainability in every thread.

Press Release: From Lab to Label

The Chemistry Between Production and Catwalks Is Finally Right

bluesign and SCTI donate the pioneering Sustainable Chemistry Index (SCI) Methodology to ZDHC aiming to advance sustainable chemistry within the textile industry.

Singapore, St. Gallen, Amsterdam – June 19, 2024

The textile industry is taking a great step forward in sustainable practices as bluesign and SCTI donate the pioneering Sustainable Chemistry Index (SCI) Methodology to ZDHC. This collaboration aims to revolutionize chemical management in the textile, leather and fashion industries, while addressing environmental impact in a holistic manner.

The Challenge of Harmful Chemicals in Fashion:

For decades, the use of hazardous chemicals in clothing has been a major challenge. Despite industry efforts with numerous overlapping standards and voluntary schemes – the textile, leather and fashion industries struggle with varying regulations, inconsistent data and a lack of common action. Inconsistent regulations, limited transparency, and little coordinated action hinder progress, while consumers do not receive information about the overall environmental impact of these industries.

A Unified Effort for Sustainable Solutions:

Leading organizations in the textile sector are elevating the conversation to tackle these issues head-on with converging assessment tools.

SCTI, a group of innovative and pioneering chemical manufacturers, aims to bring positive change to the textile industry and make sustainable chemistry the norm. bluesign, a renowned sustainability solutions provider, has extensive experience in ensuring safe and responsible chemical management, environmental and worker safety as well as resource efficiency in the production of textiles. The ZDHC Foundation, driven by major fashion brands, is on a mission to detox the fashion industry by providing tools and guidelines for sustainable chemical management.

The Start of the Sustainable Chemistry Index (SCI):

In 2022, SCTI and bluesign announced the development of the first comprehensive Sustainable Chemistry Index (SCI) for the textile industry. The pioneering work leverages best available technologies, while transcending existing chemical assessments, and introduces a one-stop-shopping tool for a broader assessment of environmental impact. Such an approach was missing. Now, the SCI introduces a standard common language for convergence and alignment throughout global textile.

Innovative Parameters for a Sustainable Future:

The SCI brings new parameters to assess how chemical products improve resource utilisation in the processes they are used along the life cycle of a garment. Key building blocks include supply chain transparency, responsible sourcing, feedstock reducing fossil dependency, product carbon footprint, resource consumption, efficiency in use during textile production, end use impact and end-of-life of consumer applications. This transparent framework makes it easier for the industry to evaluate the sustainability impact of chemicals present in a garment and promote circularity.

A Collaborative Donation to Advance the Industry:

To advance and foster industry-wide collaboration, SCTI and bluesign are donating, the SCI to ZDHC as the cornerstone of its Chemicals to Zero (CTZ-A) program. CTZ-A represents the highest level of sustainable chemistry within ZDHC. In 2024, the SCI content will undergo ZDHC’s stakeholder engagement and consultation processes, aiming to enhance the Roadmap to Zero Program by addressing sustainability and circularity. ZDHC will make the SCI content freely available to the public, enabling widespread adoption and impact.

“We have been partnering with all stakeholders involved for some time and recognized that our market has been operating with multiple isolated approaches. Within SCI content, we are converging several approaches, while raising sustainable chemistry to the benefit of our community.”

Wolfgang Schumann, RUDOLF Managing Director, SCTI Chairman, and ZDHC board member

“As a contributor in the development of Sustainable Chemistry Index, we are glad to continue the journey we have started in 2022 with this initiative, and look forward to working with our partners to further move sustainability forward in our industry.”

Daniel Rüfenacht, bluesign CEO

“Our initiative elevates collective action to new heights and enables the textile and fashion industries to make sustainable choices by taking full advantage of what solidarity can do to power change.”

Isabella Tonaco, SCTI Executive Director

“At ZDHC, our mission is to build a dynamic platform that highlights the transformative journey of sustainable chemistry in the fashion industry. By integrating the SCI as the cornerstone of Chemicals to Zero Aspirational Level and releasing it into our publicly available ZDHC Framework, we’re showcasing true thought leadership essential for driving positive change and engage our wider community of stakeholders on our way forward.”

Frank Michel, ZDHC CEO

The ZDHC program is well-positioned to complement the expertise of bluesign and SCTI and to scale its impact within a multistakeholder structure. This collaboration empowers manufacturers and brands to make informed, responsible choices in terms of chemicals and processes, committing to sustainable chemistry and benefiting society.

About SCTI

Founded in October 2020, Sustainable Chemistry for the Textile Industry (SCTI) is an alliance of leading chemical companies that strives to empower the textile and leather industries to apply sustainable, state-of-the-art chemistry solutions that protect factory workers, local communities, consumers and the environment. It has six founding members: Archroma, CHT Group, Kyung-In Synthetic Corporation (KISCO), Pulcra Chemicals, Rudolf and Tanatex Chemicals. In 2022, SCTI teamed up with bluesign to create the Sustainable Chemistry Index (SCI) that enables stakeholders to assess the sustainability of textile chemical products.

About bluesign

The bluesign® SYSTEM is the solution for sustainable textile production. It eliminates harmful substances right from the start of the manufacturing process, and it sets and controls standards for environmentally friendly and safe production. This not only ensures that the final textile product meets very stringent consumer safety requirements worldwide but also gives consumers confidence in purchasing sustainable products.

bluesign technologies ag was founded in 2000. Since then, the bluesign® SYSTEM has been adopted by worldwide leading textile and accessory manufacturers. Various significant key players in the chemical and machine industry rely on the bluesign® SYSTEM, and well-known brands in the outdoor, sportswear and fashion industry trust the extensive knowledge and services of bluesign.

About ZDHC

The ZDHC Foundation leads the fashion industry in preventing hazardous chemicals from being used in fashion production. It unites over 300 Signatories and develops guidelines, platforms and solutions that empower brands, suppliers, and chemical formulators to implement safer and sustainable chemical management.

This enables large-scale change towards zero hazardous chemical discharge across complex global supply chains. By creating the collaborative Roadmap to Zero Programme and equipping the fashion ecosystem with solutions, ZDHC plays an instrumental role in advancing the industry towards responsible chemical use that protects people and the planet.

The bluesign® Difference

‘The bluesign® difference’ is the pathway, “to meet specific sustainability criteria, with four particular areas in mind; resource efficiency, environmental impact, health and safety at work, and consumer protection,” as said by Sugath Disanayake, Assistant Manager – Chemical Sustainability at MAS Capital in the latest blog update at MAS Holdings.

At bluesign®, motivated System Partners are what allow us to complete our mission of providing sustainable solutions for the textile supply chain. Our System Partner Manufacturer, MAS, and their MAS’ Plan for Change, is a perfect example of this aligned vision. With the initiative including 12 sustainability goals and projected to be accomplished by 2025, it won’t be a small endeavor. That’s why MAS has partnered with us to ensure that we can help see these goals through.

Joining as a bluesign® System Partner means applying the bluesign® System, and in the words of our partner,

“…adopting this system helps eliminate harmful substances from the get-go and sets stringent standards for environmentally friendly manufacturing, ensuring that the final textile product meets strict consumer safety requirements worldwide, while giving consumers confidence in their purchase decisions.”

Sugath Disanayake, Assistant Manager – Chemical Sustainability at MAS Capital

MAS’s adoption of globally recognized sustainability standards demonstrates their dedication to comprehensive environmental responsibility without sacrificing product functionality, quality, or design.

A key aspect of our collaboration is the innovative ‘Input Stream Management’ approach within the bluesign® System. This methodology ensures that only approved raw materials and chemicals are utilized throughout MAS’s value chain, embedding sustainability from the very inception of garment production. This is a crucial step toward achieving MAS’s 2025 chemical management goals.

As MAS plans to implement the bluesign® System across all its dyeing facilities, this move signifies a strong commitment to sustainability and catalyzes a cleaner, more environmentally conscious future.

“Breaking new ground at MAS, we, as proponents of sustainable apparel manufacturing, celebrate the dedication of our teams’ investments in this system, as they forge a path towards a more sustainable future.”

Sugath Disanayake, Assistant Manager – Chemical Sustainability at MAS Capital

New Announcements with Soko Chimica, Pure Denim, & DONDUP

Since 2000, we have focused on various aspects including chemical management, impact reduction, worker health and safety, sustainability, and environmental sciences. One of the services we offer is the bluesign® DENIM approved product criteria.

The bluesign x Soko Chimica Partnership

We’re excited to share that we’ve forged a new partnership with the Italian chemical supplier: Soko Chimica, a business started three generations ago providing chemical auxiliaries for the textile industry.

This collaboration with Soko Chimica is groundbreaking, as they are pioneers in the chemical industry based in Italy. We believe in the power of collaboration to drive positive change, and by joining forces with Soko Chimica, we are combining our expertise and resources to redefine the standards of sustainability in the denim industry.

Soko Chimica brings a wealth of experience and innovation to the table, with a strong focus on developing environmentally friendly solutions for denim production. Their dedication to research and development aligns seamlessly with our mission to promote responsible chemical management and minimize the environmental impact of textile manufacturing processes.

Through this partnership, we will work closely with Soko Chimica to advance sustainable chemistry throughout the supply chain. By integrating our rigorous criteria and expertise into Soko Chimica’s operations, we aim to enhance transparency, traceability, and accountability in chemical management.

Italian Brand DONDUP – using bluesign Approved Fabrics from partner Pure Denim

In another exciting development, we’re thrilled to announce that the Italian fashion brand, DONDUP have committed to using bluesign® APPROVED fabrics made by our system partner manufacturer Pure Denim. This signifies a significant leap forward in the fashion industry’s pursuit of a more environmentally friendly future.

DONDUP, celebrated for its unique fusion of Italian artisanship and modern aesthetics, has steadfastly pursued measures to diminish its environmental impact over the years. By opting for bluesign® APPROVED denim fabrics by our system partner manufacturer Pure Denim, the brand reaffirms its dedication to sustainability across all facets of its manufacturing processes.

Our comprehensive sustainability framework resonates deeply with DONDUP’s ethos. The emphasis on enhancing resource efficiency, mitigating environmental harm, and safeguarding worker well-being throughout the supply chain mirrors the values that DONDUP holds dear. By adhering to our rigorous standards, DONDUP aims to elevate transparency and accountability within its operations, ultimately delivering products that epitomize the pinnacle of sustainable excellence.

bluesign CMR Solvent Phaseout Program

In a bid to enhance environmental performance and ensure consumer safety, we have launched a comprehensive phaseout program for critical solvents. Since its inception in September 2021, this initiative has gained traction among our system partner manufacturers, aiming to mitigate the adverse effects of hazardous substances.

CMR (carcinogenic, mutagenic, or toxic for reproduction) substances such as Dimethylformamide or Toluene pose significant risks to human health, particularly in industries like textile manufacturing, footwear production, and accessory manufacturing. To address these concerns, bluesign’s CMR solvent management concept advocates for the use of less hazardous alternatives and emphasizes non-regrettable substitution with water-based processes emerging as a viable solution.

As of January 1, 2022, manufacturers failing to comply with the CMR solvent management concept are barred from joining the bluesign® SYSTEM, underscoring our commitment to sustainability standards.

We at bluesign are pleased to report that a considerable number of its system partner manufacturers have already implemented the necessary measures well ahead of the previously stated 2024 deadline. This proactive approach has received praise from industry leaders like Mikio Umekawa, Managing Director at system partner Japanese manufacturer Tecone Co., Ltd. highlighting the significance of environmental stewardship in corporate management.

“Proactive efforts for environmental issues are an essential factor for our future corporate management and this has a significant impact on our vision as a textile finishing manufacturer that plays an important role in the apparel industry. It is also fact that manufacturing itself places a burden on the environment. It is a company’s mission and social responsibility to continuously decrease the resource consumption of wastewater, air emission and waste, etc. We believe that it will also contribute to further development of our company.

Mikio Umekawa, Managing Director of Tecone Co., Ltd.

TECONE Co., Ltd. conducted the bluesign® ASSESSMENT in 2019 and decided to install RTO in order to reduce VOCs in the surrounding environment. Our core product is breathable and has waterproof film. In order to bring new products to market quickly, we decided that it was extremely important to install RTO to improve our manufacturing system and reduce the impact on the environment.”

Despite this progress, we emphasize the need for full industry adoption of the CMR solvent concept. Revised timelines have been established for manufacturers currently in the implementation phase to ensure alignment with sustainability goals.

Important deadlines regarding certification of bluesign® APPROVED articles have also been outlined, focusing on compliance with CMR solvent management principles.

■ As of January 1, 2024: Certificates granted only for articles produced at production sites which comply with the CMR solvent management concept or for which an improvement plan exists.

■ As of January 1, 2027: Certificates granted only for articles which are produced at production sites which comply with the CMR solvent management concept.

For companies that have not changed to less hazardous solvent alternatives or water-based processes the following actions are mandatory according to the bluesign CMR solvent management concept:

■ Install an off-gas abatement system with an efficiency for CMR solvent(s) of at least 95% or a TOC concentration in the off-gas of less than 10 mg/m³ (all relevant emission ports) or install a recycling system with an efficiency for CMR solvents of 95% or more.

Our team extends its appreciation to all brand system partners committed to environmental sustainability. As a partner in this endeavor, bluesign emphasizes the importance of strategic investments in sustainability, despite potential material price increases. Collaboration between brands and manufacturers is crucial for the successful implementation of advanced machinery and technologies aimed at avoiding and capturing toxic fumes and reducing environmental impact.

EU parliament adopts law on banning greenwashing

bluesign® welcomed the news that the EU parliament has voted overwhelmingly for a new law banning greenwashing and misleading product information, putting a stop to generic and unsubstantiated environmental claims.

In the future, all environmental claims will need to be backed by verified data supporting those statements.

Generic phrases, that have become commonplace, such as “environmentally friendly”, “natural”, “biodegradable”, “climate neutral” or “eco” will no longer be permitted without independently assessed and certified proof.

The directive will also ban claims that a product has neutral, reduced, or positive impact by using emission offsetting schemes.

Furthermore, the use of sustainability labels will also be regulated. Only those based on official certification schemes or those established by public authorities will be allowed in the EU.

As a long-standing opponent of greenwashing in all its forms, bluesign’s head of academy, Dr Daniel Waterkamp, greeted the news as;

“A major step in empowering the consumer to make better product choices based upon true environmental performance information.”

The directive is to receive final approval from the Council; then member states will have 24 months to transpose it into national law.

The new directive will work in tandem with the green claims directive, currently being discussed at committee stage in Parliament which will provide greater detail on the specific conditions for using environmental claims.

The bluesign® SYSTEM offers its partners the help they need to fulfill their legal obligations around sustainability claims for their textile products.

bluesign® APPROVED textile articles are backed by independently assessed and verified bluesign data to secure our partners’ environmental claims.

Eco-modulation in France

Get a bonus for your textile products certified as bluesign® PRODUCT

Extended Producer Responsibility in France

Governments are increasingly legislating to improve circularity of material use in textile supply chains. France’s Extended Producer Responsibility (EPR) program is one such example. Not only does it require producers[1] to pay for the recycling and disposal of textile products at the end of their lives, it recognises and rewards producers who bring sustainably manufactured articles, such as bluesign certified products, to market. Producers are defined as

■ Manufacturers of products subject to EPR requirements that sell domestically or

■ Importers of products subject to EPR requirements or

■ Companies selling products subject to EPR requirements under own brand/name.

By law, textiles are subject to the EPR since January 1, 2007. It covers textile products, household linen and footwear sold in France. EPR also applies to numerous other economic sectors (electrical and electronic equipment, paper, packaging, lightbulbs, batteries, etc.).

The law obliges producers to provide for or contribute towards the management of waste for articles placed on the market for consumers.

To provide an individual waste collection and treatment system for sold products is for most companies a rather complex task as very specific requirements from the accrediting ministry need to be met.

An alternative solution is to transfer the responsibility to an organisation specifically dedicated to this mission (and which is already accredited by the public authorities) by financially contributing. In France, this can be done by registering with the eco-organisation Eco TLC / Refashion. Following link can be used for registration:

https://extranet.refashion.fr/en/

Producers and distributors of textile and footwear articles can register as a ‘Marketer’. Refashion will charge a per piece fee to finance a waste collection, recycling and disposal system. Companies registered at Refashion are released of their legal E.P.R obligation. The applicable fees can be retrieved under

https://refashion.fr/pro/en/2021-eco-fees-scale

How to get the ‘Eco-Modulation’ Bonus?

To encourage and reward the virtuous steps of eco-design, Refashion has implemented a bonus system called ‘eco-modulations’. Companies registered at Refashion can benefit from a per piece bonus under 3 eco-modulation schemes:

■ Bonuses for product sustainability (durability),

■ Bonuses for obtaining environmental labels,

■ Bonuses for incorporating raw materials from recycling.

bluesign is an environmental label that is recognized by Refashion. Hence, bluesign® SYSTEM PARTNERS that have their products certified as ‘bluesign® PRODUCT’ gain access to a very attractive bonus under the eco-modulation scheme. Up to 100’000 pieces per style the bonus is 0.3 Euros/piece. Above 100’000 pieces the bonus is counted as 0.03 Euros/piece. For 150’000 pieces of a style sold annually this would qualify for a bonus of

100’000 x 0.3 Cents + 50’000 x 0.03 Cents = 31’500 Euros

Those bonuses can be claimed annually. In year N (e.g. 2024) the certified article styles need to be declared. In year N+1 (e.g. 2025) the bonus will be paid upon the number of declared pieces. A detailed description how to apply for the Eco modulation bonuses can be retrieved from the Refashion website:

To benefit from bonuses in 2025 certified products with the label ‘bluesign® PRODUCTS’ must be declared before 30th of November 2024. Evidence of certification is shown by referring to the certified product style in the bluesign® GUIDE. The bluesign® GUIDE is a publicly available web application for the verification of certified articles and consumer products (www.bluesignguide.com).

Don’t miss the chance to get your bonus for your bluesign® PRODUCTS!

[1] According to Article L541-10 of the French Circular Economy Law, you are considered a producer if you are generating waste in France

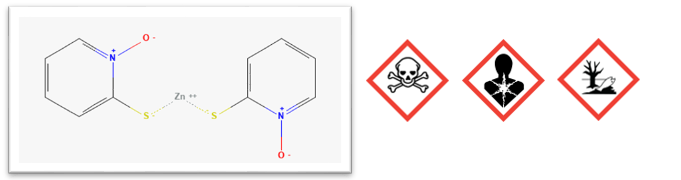

Toxic zinc pyrithione in textile products

Zinc Pyrithione is a biocide that is still widely used in the industry. Since March 2022 it is prohibited for the use in cosmetic articles in the EU market, where it was mainly used as an anti-dandruff agent and preservative.

But this substance is still applied in textile industry on fabrics and garments in order to achieve an anti-odor effect, especially for sportswear where sweating can lead to unpleasant smell. However, zinc pyrithione is a very hazardous chemical substance being classified (in the EU) as

■ Acute toxic

■ Toxic to reproduction (may damage the unborn child)

■ Very Hazardous to the aquatic environment

At bluesign we have banned the substance already 2021 in our effort to detox the textile supply chain and to protect people and the environment. The good news is: There are safer alternatives for biocides as well as non-biocidal anti-odor finishing solutions available. Our bluesign® FINDER offers currently more than 40 of those safer alternatives from 14 bluesign® SYSTEM PARTNER chemical companies.

Please check out our public freely accessible bluesign® FINDER (www.bluesignfinder.com) to search for safer biocides in the below subcategories:

■ Anti-microbiotics

■ Anti-microbiotics for Finishing

■ Anti-microbiotics for Polymers

You can contact our SYSTEM PARTNERS regarding the growing number of non-biocidal anti-odor products or find some when searching for “odor” in the general search:

Transforming Waste into Fashion with SYSTEM PARTNER ERCA Group

We Celebrate ERCA’s Brand REVECOL®: Transforming Waste into Sustainable Fashion with the help of Patagonia and YKK

Today, we proudly announce a groundbreaking development that is set to revolutionize the fashion-making process. ERCA, a key player in the sector and an Italian innovation-driven chemical group, has introduced a game-changing innovation under the brand name REVECOL®.

January 2024 marks the official birth of ERCA TCS (Textile Chemical Solutions), a business unit of ERCA S.p.A. with a focus on the textile market.

The decision to give birth to ERCA TCS comes from the desire to be a unique and innovative reference point for ERCA’s customers, with products and services designed specifically for the needs of today’s textile industry, grappling with the challenges and opportunities of sustainability and responsible production.

ERCA TCS bases its activities on the principles of “Green Chemistry” with the aim of offering the textile industry chemical solutions that make the concepts of safety, performance and circularity a reality.

The chemical auxiliaries of ERCA TCS are the result of a vision that incorporates responsible innovation, continuous research, and a desire to off er to the market effective yet ethically, environmentally, and economically sustainable solutions. Fabio Locatelli, Head of BU Textile and shareholder of ERCA explains:

“Our goal is to make ERCA TCS a reference point for sustainable innovation and help reduce the environmental impact of the textile industry by adopting innovative and truly sustainable solutions and services. A commitment to people’s well-being and responsible use of our planet’s resources has always been part of our DNA. We are always looking for innovative solutions through the development of products that are increasingly high-performing, competitive and sustainable at the same time”.

Fabio Locatelli, Head of BU Textile and shareholder of ERCA

REVECOL® by ERCA represents a paradigm shift in textile auxiliaries. This revolutionary line of chemical products is bluesign® APPROVED and derives its strength from the upcycling of a critical waste material: vegetable exhausted cooking oil. The result is a complete, safe, certified, and high-performing range of auxiliaries that promises to reshape the industry.

This innovative approach by ERCA not only underscores their commitment to environmental responsibility but also elevates their status as pioneers in sustainable textile solutions. By harnessing waste materials and turning them into valuable resources, REVECOL® addresses the ever-pressing need for circularity and sustainability in fashion production.

“The launch of REVECOL® by ERCA is a monumental step forward for the textile industry. This breakthrough innovation perfectly aligns with our mission to create a more sustainable and responsible fashion-making process. ERCA has indeed filled a crucial gap with this initiative.”

Fabian Walda, Head of Sustainability Services at bluesign

REVECOL® serves as the missing piece to boost sustainability and circularity throughout the fashion-making process. ERCA’s unwavering commitment to innovation, safety, and environmental protection is embodied in this product line, making it a symbol of progress in an industry striving for a greener future. We at bluesign applauds ERCA for its vision and dedication to transforming the industry. REVECOL® by ERCA is more than just a product; it’s a testament to the positive change that can occur when sustainability and innovation converge.

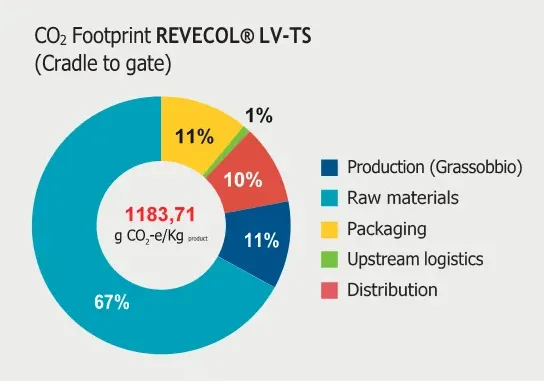

bluesign’s Carbon Footprint Calculation Reveals Remarkable Results

Thanks to our carbon footprint calculation and bluesign verified data, we are thrilled to announce that the carbon footprint of REVECOL®LV-TS is 72% lower than conventional chemical auxiliaries produced by ERCA. ERCA takes pride in being the first company in the world to have GRS certified chemical products, paving the way for circular chemical solutions, while also being bluesign® APPROVED.

Thanks to our carbon footprint calculation and bluesign verified data, we are thrilled to announce that the carbon footprint of REVECOL®LV-TS is 72% lower than conventional chemical auxiliaries produced by ERCA. ERCA takes pride in being the first company in the world to have GRS certified chemical products, paving the way for circular chemical solutions, while also being bluesign® APPROVED.

“We saw an opportunity to build a partnership with ERCA, an innovator who was pushing the boundaries of sustainability, and match them with an existing partner, YKK, that consistently delivers high-caliber, quality goods and services. Through thoughtful consideration, we designed our approach and conversion to REVECOL® LV-TS to have an outsized impact from the start. The real success is seeing this go beyond Patagonia® products and spread across supply chain partners, brands, and consumers. This is one domino to fall in how we do business to save our home planet.”

Matt Swartz, Color and Material Quality Manager at Patagonia®

“We are thrilled to be part of this unique 3‐way collaboration, exemplifying how true upcycling on a mass production scale is made possible at the center of garment manufacturing. We look forward to the expansion of REVECOL® across the entire textile industry.”

Mike Maekawa, Sales and Business Development Manager of YKK Vietnam

As part of its Sustainability Vision 2050 YKK is constantly working to deploy more sustainable chemical processes in its production. REVECOL® is not only more sustainable it is also more efficient, reducing the use of the dyeing auxiliary by 20% to 30%, helping to lower YKK’s overall chemical usage.

Development of the REVECOL® Line by ERCA’s Textile BU

The REVECOL® line was developed by ERCA’s Textile BU, which includes a research and development center, production facilities, quality control laboratory, and application laboratories and technical assistance. This levelling agent was registered together with bluesign and approved by European Union IPPC as a Best Available Technique for textile industry and is listed accordingly in the BAT reference Document (BREF). Fabio Locatelli, Head of BU Textile and shareholder of ERCA, emphasized the company’s commitment to people’s well-being and the planet’s resources, stating,

“We are always looking for innovative solutions through the development of products that are increasingly high-performing and sustainable at the same time. Our goal is to be a point of reference for sustainability and help reduce the environmental impact of the textile industry by adopting truly sustainable innovative solutions and services. We aim to counter the ‘Greenwashing monster’ that often uses communication or marketing strategies that tend to present activities as eco-sustainable. In short, our aim is to counteract a facade of ecology. If you can’t prove your claims, you are not credible, and this is unacceptable to us.”

Fabio Locatelli, Head of BU Textile and shareholder of ERCA

Dedicated Research and Development for Product Credibility

To ensure the value and credibility of their products, ERCA dedicates significant work, expertise, and time to research and development. Each product undergoes 6-8 months of study and fine-tuning, followed by an additional 6 months for fundamental analyses such as biodegradability and aquatic toxicity, conducted at specialized centers. bluesign’s third-party verified data is then obtained to independently testify to the real measure of the value of these products.

ERCA Spa Achieves GRS Certification

ERCA Spa, with the REVECOL® range, is the first chemical company in the world to obtain the prestigious GRS (Global Recycled Standard) certificate, conferred by Textile Exchange, one of the most important non-profit organizations promoting responsible and sustainable practices in garment manufacturing.

bluesign Supports ERCA’s Groundbreaking Development

bluesign enthusiastically supports the groundbreaking development achieved by ERCA with the introduction of REVECOL®. As the gold standard for more sustainable textile production, we are dedicated to promoting innovative and sustainable solutions in the industry. With ERCA’s REVECOL® and the collaboration of leading companies like Patagonia® and YKK, the possibility to reduce the environmental impact of the textile industry becomes more attainable.

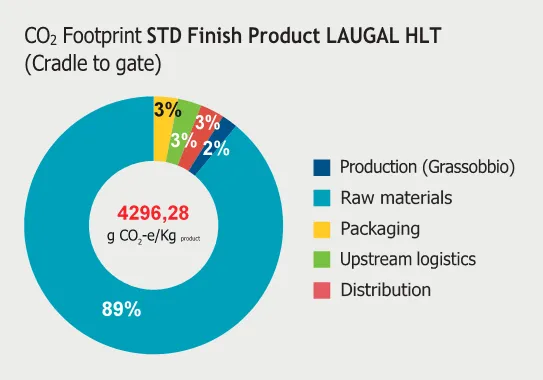

The following report details the Product Carbon Footprint (PCF) analysis performed by bluesign® ACADEMY on the following chemical products manufactured by ERCA S.p.A. in Italy: REVECOL® LV-TS and STD LAUGAL HLT. For example, these products are comparable in terms of function and performance, whereas REVECOL® LV-TS utilizes approximately 40% recycled feedstock in the chemical formulation. STD LAUGALHLT relies solely on virgin feedstock. This product carbon footprint analysis measures the environmental impact in terms of the overall global warming potential (GWP) of the products along their life cycle from cradle to customer.

In conclusion, the product carbon footprint calculation at hand shows that the GWP of REVECOL LV-TS is significantly lower than the GWP of STD LAUGAL HLT. It is clear that the main reason for this is the replacement of virgin feedstock with recycled feedstock in the chemical formulation of REVECOL® LV-TS. It can be concluded that REVECOL LV-TS has about a 72 % lower GWP compared to STD LAUGAL HLT.

BLUESIGN® academy white paper: new york fashion act

The Fashion Act is intended to lead the way on sustainable apparel production, in much the same way that the State of California was in the vanguard of vehicle emissions legislation in the US some years

The european commission green claims directive

Among the many new initiatives being prepared by legislative bodies across the globe, the European Commission’s far-reaching Green Deal initiative has recently seen the tabling of their Green Claims Directive. It calls for greater regulation of all environmental claims, through certification by an accredited body. This represents a major shift and moves the topic of ‘sustainability” from, what has often been little more than a marketing slogan to an essential brand commitment and purpose.

This bluesign® ACADEMY White Paper provides an overview of the Directive. If you would like to speak to us about forthcoming regulatory change please contact us at bluesign@academy.com

OVERVIEW

- The European Green Deal tackles false environmental claims by ensuring that buyers receive reliable, comparable, and verifiable information to make more sustainable decisions and to reduce ‘green washing’.

- European Commission (EC) wants environmental claims based on environmental impacts along products’ life cycles to be substantiated.

- EC will regulate use of environmental claims by establishing solid and harmonized calculation methods covering the full value chain.

CLAIMS

MISLEADING CLAIMS: THE SCALE OF THE PROBLEM

- In spite of consumers’ willingness to contribute to a greener and more circular economy this is hampered by a lack of trust in the credibility of environmental claims and the proliferation of misleading commercial practices related to the environmental sustainability of products.

- Greenwashing and lack of transparency and credibility of environmental labels, occur at various stages of the consumption journey.

- The European Commission’s 2020 study found that of environmental claims 53.3% provide vague, misleading, or unfounded information about products’ environmental characteristics across the EU and across a wide range of product categories.

- 40% of environmental claims were unsubstantiated by verifiable evidence.

- Of 344 sustainability claims assessed by EU Member State Consumer Protection authorities, in 57.5% instances the claim’s accuracy could not be judged.

- In 50% of cases Member State Authorities had difficulties identifying whether claims covered the whole product or only one of its components

- In 36% of cases, whether it referred to the company or only certain products, and:

- In 75% of cases which stage of the products lifecycle it covered (75%).

- Most stakeholders consulted agreed that greenwashing is a problem, with the noticeable exception of industry representatives

FRAMEWORK FOR FUTURE CLAIMS

The proposal requires that in future explicit environmental claims shall be based on an assessment that at minimum is defined by criteria that are not misleading, and that the claim:

- relies on recognized scientific evidence and state of the art technical knowledge;

- demonstrates the significance of impacts, aspects, and performance from a life-cycle perspective;

- accounts for all significant aspects and impacts to assess the performance

- demonstrates whether the claim is accurate for the whole product or only for parts of it (for the whole life cycle or only for certain stages, for all the trader’s activities or only a part of them);

- demonstrates that the claim is not equivalent to requirements imposed by law;

provides information on whether the product performs environmentally significantly better than what is common practice;

- identifies whether a positive achievement leads to significant worsening of another impact;

- requires greenhouse gas offsets to be reported in a transparent manner;

- includes accurate primary or secondary information.

LABELLING

ENVIRONMENTAL LABELLING: THE ISSUES

(Environmental labels: i.e., those covering predominantly environmental aspects of a product or trader)

An assessment of 232 active ecolabels in the EU also examined their verification and certification aspects and concluded that almost half of the labels’ verification was either weak or not carried out.

Over a quarter (27%) of participants said “the proliferation and/or lack of transparency/ understanding/reliability of sustainability logos/labels on products and services” was an obstacle to empowering consumers.

34% of businesses identified the “the proliferation and/or lack of transparency / understanding / reliability of sustainability logos / labels” as an obstacle.

Companies that make the effort to adhere to or develop reliable environmental labelling schemes are disadvantaged compared to companies that use unreliable environmental labels as consumers often cannot tell the difference.

Companies that offer truly sustainable products are disadvantaged compared to those that do not.

FRAMEWORK FOR FUTURE LABELLING

The mechanism that will be used to ensure that in future, environmental labelling is neither vague, misleading, nor unfounded, will be through an amendment to the Unfair Commercial Practices Directive. It will:

- List product characteristics about which a trader should not deceive a consumer is to include ‘environmental or social impact, ‘durability’ and ‘reparability’.

- The list of actions which are to be considered misleading if they cause or are likely to cause the average consumers to take a transactional decision that they would not have otherwise taken, ‘making an environmental claim related to future environmental performance without clear, objective, and verifiable commitments and targets and an independent monitoring system.

- The list of unfair commercial practices will expand to include:

- Displaying a sustainability label which is not based on a certification scheme or not established by public authorities.

- Making a generic environmental claim for which the trader is not able to demonstrate recognized excellent environmental performance relevant to the claim.

- Making an environmental claim about the entire product when it concerns only a certain aspect of the product.

- Presenting requirements imposed by law on all products in the relevant product category on the Union market as a distinctive feature of the trader’s offer.

- The proposal is for a stand-alone legal instrument that …sets a framework for the substantiation of voluntary environmental claims.

- Member States shall provide that penalties and measures for infringements of this Directive shall include:-

- fines which effectively deprive those responsible of the economic benefits derived from their infringements, and increasing the level of such fines for repeated infringements;

- confiscation of revenues gained by the trader from a transaction with the relevant products concerned;

- temporary exclusion for a maximum period of 12 months from public procurement processes and from access to public funding, including tendering procedures, grants, and concessions.

- The maximum amount of such fines being at least at 4 % of the trader’s annual turnover in the Member State or Member States concerned.

VERIFICATION

ENSURING IMPARTIAL VERIFICATION OF FUTURE CLAIMS

An entity verifying environmental claims:

- Shall be a third-party conformity assessment body formally accredited by a nationally recognized certifying entity.

- Accreditation given to a claim shall be based upon an evaluation in compliance with the requirements in below:

- the verifier shall be independent of the product bearing, or the trader associated to, the environmental claim;

- the verifier, its top-level management, and the personnel responsible for carrying out the verification tasks shall not engage in any activity that may conflict with their independence of judgement or integrity in relation to the verification activities;

- the verifier and its personnel shall carry out the verification activities with the highest degree of professional integrity and the requisite technical competence and shall be free from all pressures and inducements, particularly financial, which might influence their judgement or the results of their verification activities,

- the verifier shall have the expertise, equipment and infrastructure required to perform the verification activities in relation to which it has been accredited;

- the verifier shall have a sufficient number of suitably qualified and experienced personnel responsible for carrying out the verification tasks;

- the personnel of a verifier shall observe professional secrecy with regard to all information obtained in carrying out the verification tasks;